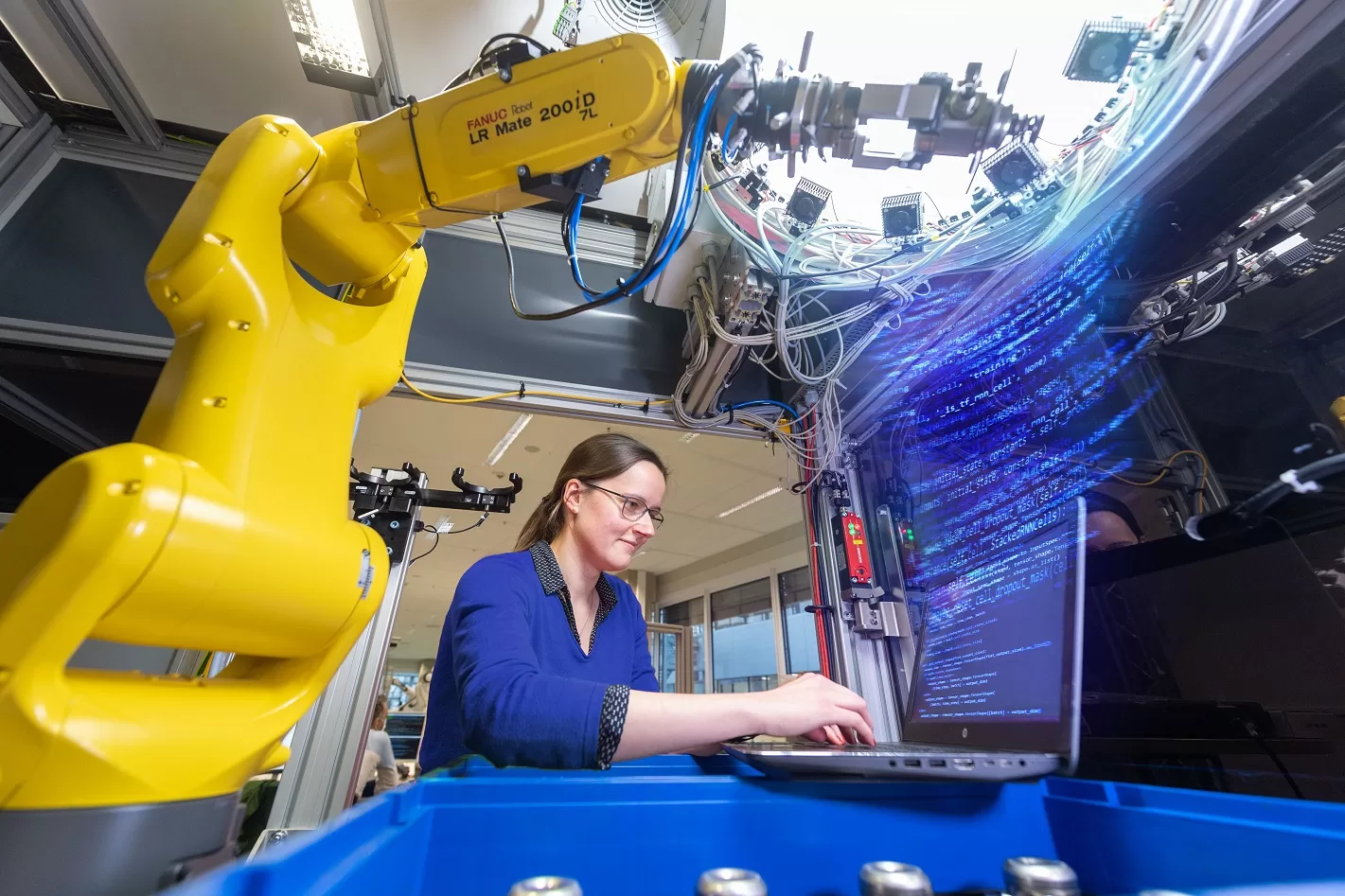

- Generative AI: Bosch is launching pilot projects in its plants. Generative AI is expected to reduce time needed for rollout and setup of AI solutions from several months to just a few weeks.

- AI in practice: nearly half of all Bosch plants are already using AI in manufacturing. The focus is on production scheduling, monitoring, and control.

- AI pioneers: World Economic Forum has singled out Bosch plants as Industry 4.0 “lighthouses.” In 2023, the Bosch plant in Bursa was commended for its work in the field of artificial intelligence.

Bosch is piloting generative AI and foundation models in manufacturing. In initial projects in two Bosch plants in Germany, generative AI creates synthetic images in order to develop and scale AI solutions for optical inspection and optimize existing AI models. Bosch expects that this will reduce the time needed for planning, launching, and ramping up AI applications from the current six to twelve months to just a few weeks. Following successful piloting, this service for generating synthetic data is to be offered to all Bosch locations.

Nearly half of all Bosch plants are already using AI in their manufacturing operations. With the help of generative AI, we’re not only improving existing AI solutions, but we’re also laying the foundations for the optimum take-up of this future technology in our global manufacturing network

Stefan Hartung, chairman of the board of management of Robert Bosch GmbH.

There are sound economic reasons for this move: depending on the size of the plant and type of production, artificial intelligence can be used to achieve productivity gains and six- to seven-figure cost savings – per year and plant. “AI has excellent potential for innovation and can make human work even more productive. As a manufacturing company, established factory outfitter, and Industry 4.0 trendsetter, Bosch aims to play a leading role in the development and application of industrial AI,” Hartung says.

AI in practice: Bosch projects deliver substantial benefit

Bosch pilot plants are already using AI in production scheduling, monitoring, and control. At the plant in Hildesheim, for example, AI-based data analysis has helped reduce cycle times during the production ramp-up of new lines by 15 percent. At the plant in Stuttgart-Feuerbach, new algorithms cut component-testing processes from three and a half to three minutes. “With generative AI, we’re now taking the next step in the evolution of artificial intelligence and advancing modern manufacturing to a new level,” says Tanja Rueckert, member of the Bosch board of management and chief digital officer.

In this process, Bosch can build on its own expertise: the software models for generative AI were developed by Bosch research and are now being implemented in the field by Bosch factories. One plant uses an AI method of synthetically generated images to reliably inspect welds of copper wires in electric motor production, while another focuses on the quality assurance of high-pressure pumps.

AI boost: generative AI pushes the boundaries of feasibility

For years, the Feuerbach plant inspected fuel-injection components manually. The nature and complexity of the products, as well as differences in the structure of the production lines, meant that neither rule-based nor AI-assisted optical inspection was possible. The new approach is a scalable generative AI that recognizes variants of a product and error patterns and takes into account different arrangements and sequences in the production process. This is based on a foundation model developed by Bosch research and fed by large data sets from the Bosch manufacturing network. Synthetically generated data is used to refine the model and customize it for on-site applications.

This is expected to make the AI capable of inspecting components independently, only submitting cases to visual inspectors where it is unsure. At the Hildesheim plant, synthetically generated images have already been successfully used for training purposes in the first standard systems in electric motor production. The human eye cannot distinguish the artificially generated images from real ones. The plant expects that project duration will be six months shorter with the new approach than with conventional methods, leading to annual productivity increases in the six figure euro range. Bosch plans to expand the AI approach to other locations. “In our work to develop AI solutions, we’re unlocking the potential offered by the Bosch manufacturing network and its roughly 230 plants. And we are using new technologies. Generative AI helps to harmonize individualization and scaling – the technology gives us the best of both worlds,” Rueckert says.

AI status: widely used in Bosch plants

Many Bosch plants have one thing in common: not only are they AI pioneers, but they also focus consistently on Industry 4.0. “Bosch has been digitalizing and connecting its own plants and those of its customers for more than ten years. Now we’re combining Industry 4.0 with artificial intelligence: connected manufacturing provides data and AI evaluates it,” Rueckert says. Errors are detected at an early stage, machine downtimes are kept to a minimum, scrap is reduced, and energy is applied in a focused way. “The use of AI will make factories more efficient, more productive, and more eco-friendly,” she adds.

For example, Bosch research has developed an AI-based system that identifies anomalies and malfunctions in the manufacturing process and improves product quality. This software is now in use in around 50 Bosch plants, with over 2,000 production lines connected. Many Bosch plants also use artificial intelligence in the optical inspection of components. For example, over 20 plants use Machine Vision AI, a solution designed by Bosch’s special-purpose machinery unit that helps detect hard-to-identify features, such as scratches and chipping on surfaces and defects in weld seams.

AI pioneers: World Economic Forum commends Bosch plants

The Bosch plant in Bursa, Turkey, illustrates what AI can achieve in manufacturing. Starting from an already high level of technical expertise, the plant has used AI to further improve manufacturing quality: it has reduced water consumption by 30 percent, energy consumption by 6 percent, and scrap by 9 percent, while also increasing plant efficiency by almost 10 percent. This year, these achievements prompted the World Economic Forum (WEF) to single out the plant in Bursa as an Industry 4.0 lighthouse. This is the fourth time a Bosch plant has received such recognition from the World Economic Forum, and the second time specifically for developments in the field of artificial intelligence. All this shows that “AI’s importance is historic. It will fundamentally change industrial production – for the better,” Rueckert says.