Audi is kicking off the largest model initiative in its history with the start of production for the new Audi Q6 e-tron series based on the Premium Platform Electric (PPE). The first fully electric model series to be made in Ingolstadt demonstrates how Audi is preparing and qualifying its employees for the new era of electric mobility.

“With 500 additional jobs for the production of our new fully electric Q6 e-tron, we are showing that our transition to electric mobility is a driver of job creation. By guaranteeing a high volume of employment and new jobs, electrification will increase job security at our German locations,” says Xavier Ros, Chief Human Resources Officer at Audi. That is why, Audi is also considering temporary employees who already work in Ingolstadt in the application process.

In addition to creating jobs specifically for e-mobility, the transformation of the workforce is an essential part of Audi’s transition to electric mobility. “Our employees who continue to gain qualifications and reinvent themselves professionally is what makes the transition to electric mobility possible,” adds Ros. To this end, Audi provides numerous training and development opportunities for employees. The focus is on developing and qualifying existing employees for new tasks. Over the past 18 months, Audi has qualified around 8,300 employees from Production, Technical Development, and Sales in Ingolstadt ahead of the launch of the Q6 e-tron series. In 2022 alone, AUDI AG invested around 150 million euros into the training and development of its employees. And at Audi Hungaria in Győr, where the electric drivetrain for the Audi Q6 e-tron is made, around 2,000 employees have also been trained for electrification since 2022.

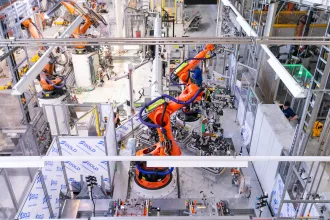

Production of the Audi Q6 e-tron model series will make the headquarters in Ingolstadt the first Audi site in Germany to have its own battery assembly facility. “We are actively shaping the structural transition to e-mobility. With the battery assembly we have already created 300 attractive and future-proof jobs at our Ingolstadt site. At the same time, valuable know-how that will be employed in the production of fully electric vehicles at all of our factories is being created. We are using electrification for a comprehensive realignment of our worldwide production network; battery assembly in Ingolstadt is a part of this, says Gerd Walker, Chief Production Officer at Audi.

360factory: the future of Audi production

With its corporate strategy Vorsprung 2030, Audi made the decision early on to phase out combustion engines: Based on this decision, Audi is now taking steps to prepare all its sites for the production of electric cars. By the end of the decade, every Audi location worldwide will produce at least one fully electric model. Audi is using the retooling of its facilities to comprehensively reinvent its plants and production processes.

Audi Production has set ambitious goals for the transformation of its plants as part of its 360factory strategy and is taking a holistic approach to implementing them. Optimal production processes, digitalization as the foundation for efficiency gains, sustainable and resilient supply chains, a highly flexible production network, and clear sustainability goals are some of the strategic fields Audi Production is leveraging. “At the same time, we are creating new job opportunities at our locations. This is because we are committed to tackling the transformation together with employees within our existing production network,” explains Ros. As the next step, the company is setting up its own battery module production facility in Ingolstadt for upcoming fully electric model series.

Targeted job creation

As part of its job creation activities in the area of production, Audi is looking for new employees with metalworking or electrical training and corresponding professional experience. Applications are now being accepted online. The first round of selection interviews will take place on July 21, 2023, at Audi in Ingolstadt. Further dates will follow and will be announced online on the same website. Candidates will be invited to the selection interviews in person after their application has been received and cleared a preselection process.

As the company also continues to deepen its software expertise for the digitalization of its models, the search for software experts for Audi’s Technical Development is in full swing. Applicants are also invited to apply for open positions on the Audi Job Portal.