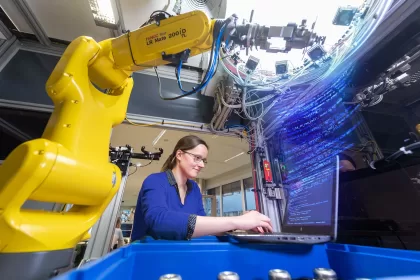

- Smart factory: Audi and Fraunhofer Institutes are evaluating the use of AI and robotics during the picking process in a real-world laboratory

- Needs-based approach: new technologies to reduce employees’ workload

- Digital ecosystem: as part of the “Automotive Initiative 2025”, Audi works closely with Fraunhofer IAO to advance the digital transformation of factories

As a real-world laboratory, low-volume production at Böllinger Höfe plays a key role in advancing digitalization in production and logistics in line with Audi’s 360factory. Audi Sport is collaborating with partners from the Fraunhofer Heilbronn Research and Innovation Centers HNFIZ to explore the future of the picking process in automotive manufacturing using a new approach. First, a needs analysis identified the areas and activities with the greatest potential to optimize processes and reduce employees’ workload. In the next step, the research partners will now trial a wide range of technologies from the fields of artificial intelligence (AI) and robotics in a designated area in production until the end of the year.

The manual picking process in automotive production involves the targeted retrieval and collection of vehicle components from various logistics containers in an area known as the “supermarket” to supply the assembly line. Audi Sport is working with the Fraunhofer IAO and IPA institutes to investigate which technological approaches can be best integrated into the picking process in everyday work – for example, to minimize the number of incorrect parts selected, improve supply to the assembly line and reduce physical strain on employees. “Low-volume production at Böllinger Höfe is ideal for such purposes. We produce the Audi e-tron GT family, for example. These vehicles feature a high degree of customization. That makes the picking process particularly complex and challenging due to the large number of different parts it involves,” says Alexander Müller, Head of Logistics at Audi Sport GmbH.

One aspect that sets the current research project apart is the upstream needs analysis. It involves employees performing the picking process while wearing smart glasses that use infrared cameras to record the position and movement of their eyes. The eye-tracking glasses collect data such as pupil diameter and gaze direction. This enables them to tell where exactly a person is looking, and which activities are most mentally strenuous. “The approach of first identifying where employees need support and then determining how new technologies can be used to address these needs reflects our overarching goal. We want to improve efficiency as well as the interaction between people and technology in the plant. To this end, we are bringing innovations and research to future users on site and evaluating possible solutions together,” explains Müller.

AI and mobile robotics as research fields

The trials are taking place in a dedicated real-world laboratory area at Böllinger Höfe. In the logistics section, the researchers are testing various technological aids and approaches using a true-to-life copy of the “supermarket” where the picking process takes place. Firstly, Audi and the two Fraunhofer Institutes want to find out what potential applications of artificial intelligence (AI), such as computer vision, can aid manual picking and how these technological solutions can best support humans. Secondly, the partners are investigating the potential applications of mobile robots. The autonomous articulated-arm robots are equipped with various grippers and 3D sensor technology. Real vehicle orders are used as test cases to suitably simulate the use of AI and robotics solutions. Repeated testing and evaluation in a realistic environment allow the requirements for their practical use to be better understood and integrated into the development process.

This, together with the direct involvement of employees in this process, results in tailored solutions. “With the real-world laboratory in Audi Sport plant at Böllinger Höfe, we are opening a new chapter in the collaboration between science and industry. There, we have the opportunity to scientifically test the use of new technologies in real-world work processes for the first time. The central input comes from the workers themselves, who evaluate the benefits of artificial intelligence, sensor technology, and robotics in their familiar production environment,” says Bernd Bienzeisler, Head of the Cognitive Service Systems Research and Innovation Center KODIS at Fraunhofer IAO.

AI25: digital factory transformation in the digital ecosystem

The project builds upon ongoing activities and successful collaborations within the AI25 initiative. Audi launched the Automotive Initiative 2025 (AI25) together with Fraunhofer IAO and other partners from the fields of science, research, and technology. AI25 sees itself as a competence network for advancing the digital transformation of automotive production. In the Böllinger Höfe real-world laboratory, innovative solutions from the conducted research projects are tested and developed to production readiness. The initiative is part of a broader ecosystem in the Heilbronn region, emerging around the Innovation Park for Artificial Intelligence (IPAI).