- The Audi headquarters in Ingolstadt is the first Audi plant in Germany with its own battery assembly facility

- Integration of production into existing body shop and assembly structures

- Board Member for Production and Logistics Gerd Walker: “We are harnessing electrification to comprehensively transform our existing plants.”

Since production started in late 2023, the Audi Q6 e-tron series has been the first high-volume fully electric model series that Audi has produced at its headquarters in Ingolstadt. In keeping with the brand’s 360factory production strategy, Audi has integrated individual production steps into existing body shop and assembly structures and processes. Since January 1, 2024, Audi has also been manufacturing at its Ingolstadt site with net-zero emissions1. Moreover, the brand with the four rings’ headquarters is the first Audi location in Germany to have its own battery assembly facility.

Audi CEO Gernot Döllner emphasizes the significance of the first model based on the Premium Platform Electric (PPE): “The PPE, and with it the Q6 e-tron series, form the basis for subsequent electric Audi models. In this way, we are taking a decisive step towards offering an electric model in all core segments in the medium term.” Audi Board Member for Production and Logistics Gerd Walker considers the start of production in late 2023 as an important milestone for the 360factory production strategy: “By the end of the decade, we will have successively equipped all Audi locations for electric mobility. We are harnessing electrification to comprehensively transform our existing plants. With the production of the Q6 e-tron series, the Ingolstadt plant is taking the next step towards becoming a 360factory.” Audi has a clear vision for the production of the future.

As part of this holistic, sustainable approach, the company is modernizing, digitalizing, and transforming its existing plants. The Audi Q6 e-tron series, as well as all other vehicles built at the site, have been made with net zero emissions1 since 2024.

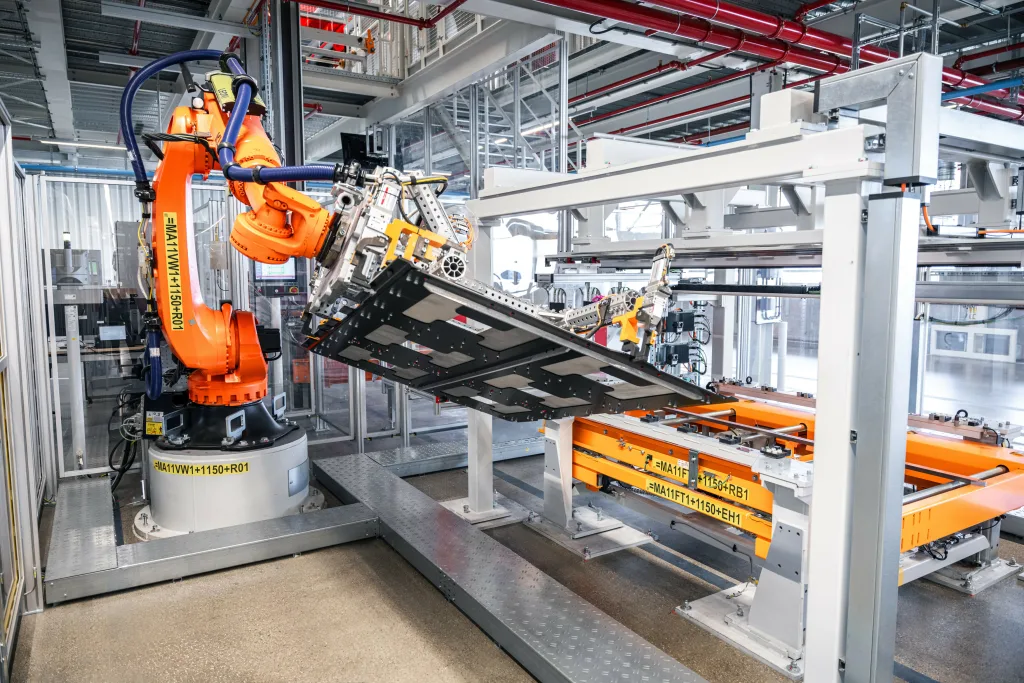

State-of-the-art production technology in the new battery assembly facility

One example of how Audi is modernizing and expanding its existing systems is the new battery assembly facility for PPE models. On an area of around 30,000 square meters (323,000 sq ft), 300 employees work in three shifts with an automation rate of almost 90 percent to assemble up to 1,000 high-voltage batteries per day for PPE-based models. “In this way, we are increasing our vertical range of manufacture while also bringing additional skills and technologies to the location,” explains Board Member for Production and Logistics Walker.

The new facility, which is located in a dedicated battery assembly hall at the Logistics and Goods Transport Center (GVZ) in Ingolstadt, is powered exclusively by green electricity. This also allows Audi to achieve even greater flexibility and efficiency in production without sealing additional areas for new buildings.

Electric motors for PPE from the world’s largest powertrain plant in Győr

Ingolstadt is sourcing the electric motors for the new Premium Platform Electric (PPE) technology platform from the world’s largest powertrain plant in Győr, Hungary. Audi Hungaria manufactures electric motors for the PPE on three newly installed production lines. The motors are then transported to Ingolstadt by the transportation and logistics company DB Cargo with zero emissions.

Audi has been producing at the Győr site with net zero emissions since 2020. “Sustainable production in existing plants is the core of our 360factory manufacturing strategy and an integral step on our path towards building a future-proof production network,” says Walker.

Retooling and a flexible equipment concept in the body shop

In order to make production of the Q6 e-tron series sustainable and efficient at the same time, Audi has integrated production domains such as the body shop for the PPE into existing structures. The bodies for the PPE models are assembled at the Ingolstadt plant on an area of around 148,000 square meters (1.6 million sq ft). There, 328 employees per shift and 1,150 robots build the body components for the Q6 e-tron series with an automation rate of 87 percent.

The highly flexible equipment will also enable the virtually seamless launch of future models. In order to make sustainable and synergistic use of resources, Audi is reusing more than 600 machines such as robots that were already used to produce other Audi models in the body shop for the production of PPE bodies. Audi is also putting a new fleet of more than 40 automated guided vehicles (AGVs) into operation for the Q6 e-tron series. The AGVs supply materials in the hall and also supply the body shop with the required parts in automated operation.

Assembly of PPE models with existing equipment

Audi consistently relies on existing systems and equipment for assembly. For example, the Audi Q6 e-tron series was seamlessly integrated into the assembly line previously used for the Audi A4 and A5 models. It took Audi eight stages of modification to integrate the PPE models into its assembly operations.

Higher automation in the paint shop

Production has also extended the paint shop for the new fully electric series. Among other changes, the dryer after the cathodic dip coating (CDC) process step was extended and a new integrated procedure for automatically sealing holes was introduced. After CDC, robots use adhesive pads to seal about 70 holes in the bodies, each of which is measured individually for this step. Previously, employees had to manually perform this part of the process. Audi upgraded the dryer to meet the higher energy requirements for curing the bodies after CDC.

This modification ensures all parts of the body reach the target temperature of 160 °C (320 °F) required for curing the CDC. The Ingolstadt paint shop also uses automated production technology that helps detect, evaluate, and process surface irregularities. This makes it possible to objectively inspect finished surfaces, increasing process reliability and making quality monitoring more transparent. In the first step, robots scan the vehicle surfaces using an automated measuring system. This process is the basis for finishing, which is also an automated process. Each finishing robot is equipped with a grinding and polishing tool. In the subsequent step, employees inspect the processed areas on large screens.

Flexible equipment concept for hot forming

At the press shop in Münchsmünster, a team of experts has been working hard to upgrade the hot-forming process for the PPE. Hot forming is primarily used to produce safety-related components: This process gives extra stability and crash safety to sheet metal parts for the body structure of vehicles on the PPE, such as A- and B-pillars, as well as parts of the longitudinal members.

After being heated to around 950 °C (1,742 °F) in a special furnace, sheets of metal are formed into the desired component in a forming press using the appropriate template. By locally cooling the heated metal using air vents, Audi can influence the strength of the components as needed to further optimize crash performance while reducing the weight of the body.

Due to the high hardness of the material, it is then necessary to use special lasers to cut the desired contours into the components.

In addition to components for models based on the PPE, the production equipment is also being used to produce components for combustion-engine models based on the PPC (Premium Platform Combustion). This new level of flexibility means the equipment can be used to manufacture a total of 44 components in Münchsmünster. Changing the setup of the laser cells and forming presses is fully automated and time-optimized, resulting in a plant output of around 20,000 individual parts per working day.