- In late 1899, Laurin & Klement introduced their first motorcycles powered by single-cylinder engines designed in-house

- Over the past 125 years, the Mladá Boleslav-based car manufacturer has produced 15 million engines, making it one of the world’s longest-established powertrain manufacturers

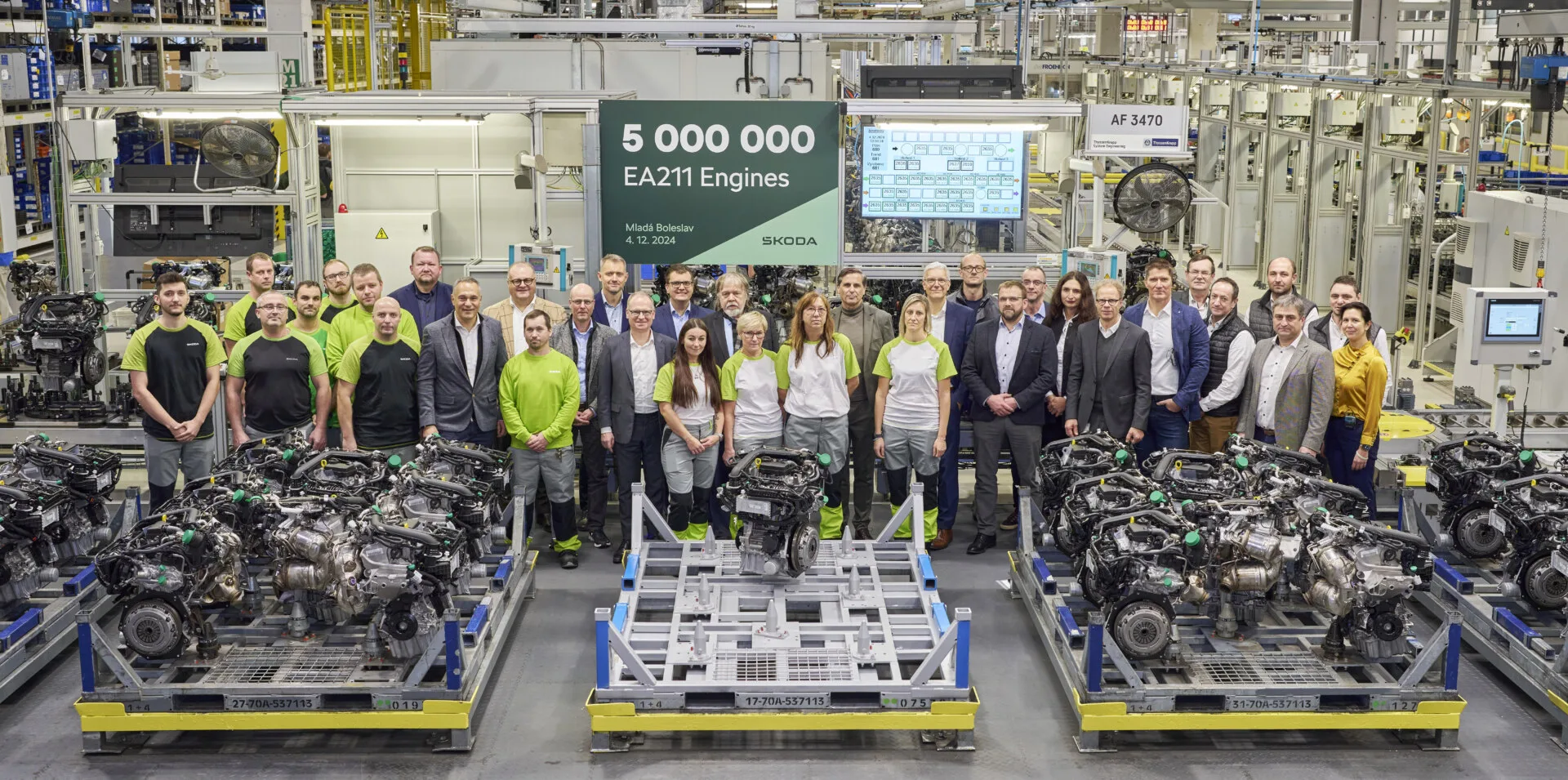

- Škoda Auto is marking these historic milestones with the production of the five-millionth engine in the EA 211 series

- Škoda Auto is responsible for developing petrol engines of up to 1.6 litres for the entire Volkswagen Group

Engines have been developed and manufactured in Mladá Boleslav for 125 years, making Škoda one of the world’s longest-standing powertrain producers. The company is celebrating this significant milestone with the five-millionth engine in the EA 211 series. Since 1899, more than 15 million engines have been produced, including technically outstanding units like the first inline eight-cylinder engine in Central Europe (1907), pressure-cast aluminium block engines in the one-litre class (1964), and modern MPI and TSI powertrains. Škoda’s expertise in engine production is further underscored by the Volkswagen Group’s decision to entrust the brand with the development of petrol engines up to 1.6 litres for the entire Group.

Historical milestones: from motorcycles and aircraft engines to automotive V8s

Just four years after the founding of Laurin & Klement in 1895, the Slavia bicycle range was expanded to include an auxiliary petrol engine, followed shortly by the first Slavia Type A motorcycle in 1899. This motorcycle featured an in-house designed single-cylinder engine delivering 1.25 hp, marking the beginning of the 125-year tradition of engine production in Mladá Boleslav.

In 1904, the L&K Type CCCC became the world’s first motorcycle powered by an inline four-cylinder engine. The following year, a combustion engine—a four-stroke, liquid-cooled, one-litre V-twin—was installed in Laurin & Klement’s first car, the Voiturette A. In 1907, Laurin & Klement introduced the FF, the first inline eight-cylinder engine of its kind in Central Europe, followed by the production of the L&K Type EL aircraft engine in 1910.

“Škoda Auto’s tradition of engine development and production began 125 years ago and is demonstrated by the impressive milestone of 15 million engines manufactured in Mladá Boleslav to date. We are marking this achievement with the production of the five-millionth EA211 engine, used in various Volkswagen Group vehicles across Europe and in the dynamic growth market of India. I am grateful to the entire team for this remarkable accomplishment, which highlights Škoda’s expertise in powertrain production within the Volkswagen Group.”

Andreas Dick, Škoda Auto Board Member for Production and Logistics

In 1929, under the Škoda brand, large-scale assembly-line production started in Mladá Boleslav. The engine portfolio at that time included reliable one-litre four-cylinder engines as well as inline six- and eight-cylinder units and diesel engines. Particularly significant for engine development and production in Mladá Boleslav was the introduction of pressure-cast aluminium engine blocks for the Škoda 1000MB in 1964. This original Czech patent was pioneering for its time. Today, the method of pressure-cast aluminium continues to be used in the latest EA 211 series engines.

Five million EA 211 engines: Škoda’s vital role within the Volkswagen Group

In 1991, Škoda joined the Volkswagen Group and began supplying engines to other Group brands just six years later. The company’s ability to develop powerful, efficient, state-of-the-art engines, coupled with high precision in large-scale production was underlined in 2012 with the start of production of the EA 211 engine series, beginning with then-new 1.2 and 1.4 TSI. Škoda subsequently assumed full responsibility for developing MPI engines for the entire Volkswagen Group and, in 2014, opened an ultra-modern engine centre, which includes advanced testing facilities capable of handling engines with outputs of up to 400 kW.

In March 2023, the Volkswagen Group decided to gradually transfer responsibility for the entire EA211 engine series to Škoda. Focusing on efficiency, economy, and compliance with new emissions standards through innovative technical solutions, the company now develops combustion engines for 50 model ranges across seven Volkswagen Group brands. These include the 1.0 MPI, 1.6 MPI, 1.0 TSI, 1.4 TSI (PHEV), and 1.5 TSI engines.

Amid the ongoing transformation of the automotive industry, Škoda Auto is offering customers the best of both worlds, with a portfolio featuring ICE and electric models to provide greater choice. The company is also leveraging its technical expertise to develop battery systems for electric vehicles based on the Modular Electrification Toolkit used across the entire Group. Recently, the Czech carmaker celebrated the production of its 1,000,000th battery system.