- New competence centre for development of innovative, high-performance battery cells and new manufacturing processes

- Ola Källenius: “Our goal is to reduce battery costs by more than 30 percent in the coming years”

- In 2024, Mercedes-Benz will invest 14 billion euros in research and development and in its plants – a significant proportion will be channelled into the development of batteries and electric drive systems

- New “Industrial Cell Lab” covers the entire product and process chain of cell development and production, and enables the development of expertise for an economical manufacturing process

- Investments in the three-digit million range strengthen Stuttgart-Untertürkheim as a high-tech location for drive technologies

- Sustainable building concept: recycled concrete, green roof including photovoltaics

Mercedes-Benz is significantly strengthening its development activities in battery technology. In a ceremony attended by the German Federal Minister of Economic Affairs Robert Habeck, Baden‑Württemberg’s Minister-President Winfried Kretschmann and other high-ranking guests, Mercedes‑Benz opened the eCampus at the heart of its headquarters in Stuttgart-Untertürkheim.

It is the competence centre for the development of cells and batteries for the future electric vehicles of the brand with the star. The aim is to develop innovative chemical compositions and optimised production processes for high-performance cells with “Mercedes-Benz DNA” and reduce battery costs by more than 30 percent in the coming years. The Mercedes-Benz eCampus covers the entire field of battery and cell technology. It ranges from the development and evaluation of new cell chemistries and industrial-scale cell production to the testing and certification of complete battery units.

“The opening of the Mercedes-Benz eCampus marks an important step in our sustainable business strategy. It is our ambition to also play a leading technological role in electric mobility. The eCampus brings us closer to this goal. The work carried out here will help to reduce battery costs by more than 30 percent in the coming years. By locating the eCampus at the heart of our centre for research and development of drive systems, it signifies a clear commitment to a more sustainable future and to the long heritage of our Stuttgart-Untertürkheim location.”

Ola Källenius, Chairman of the Board of Management of Mercedes-Benz Group AG

Mercedes-Benz eCampus: concentrated expertise in battery technologies with “Mercedes-Benz DNA”

Mercedes-Benz is developing various forms of cell chemistry. Among other things, the company is working on lithium-ion cells with high-energy anodes based on silicon composites and innovative cobalt-free cathode chemistries, as well as on solid-state battery technology. The aim is to develop the best possible cells with

“Mercedes-Benz DNA” for high energy density, fast-charging capability and performance and to build up expertise for their industrialisation. Specifically, the energy density can be increased to up to 900 Wh/l through the use of new technologies such as high-silicon anodes or solid electrolytes. The only way to scale up production effectively is through comprehensive knowledge of cell chemistry and design. The knowledge gained flows into series production of battery cells at partner companies – for use in future generations of Mercedes-Benz batteries. The importance of mastering cell chemistry for the development of future products has been demonstrated by the VISION EQXX technology programme, for example. Thanks to a powerful battery with pioneering cell chemistry, this vehicle has set distance and efficiency records for electric vehicles on several journeys.

Operations at the new competence centre for battery technologies in the heart of the Stuttgart-Untertürkheim plant will start in two stages. The approximately 10,000-square-metre factory for the industrial production of battery cells has started operations after a construction period of around two years. State-of-the-art production facilities in the “Industrial Cell Lab” make it possible to manufacture and test battery cells with different chemistries on an industrial scale. Several tens of thousands of cells can be produced here every year for the development of future battery generations. The production process consists of a series of automated and manual steps. It covers all battery cell manufacturing steps from electrode production to cell assembly including electrolyte filling, forming with the first charging and discharging processes and finishing.

The cell production process has a major influence on the quality of the battery. Mercedes-Benz has therefore the ambition to not only master the chemical composition of the cells, but also the industrial manufacturing process. The new Industrial Cell Lab enables the company to gain expertise in the economical production of cells with “Mercedes-Benz DNA”. It thus complements the two existing cell laboratories: Novel cell chemistries and advanced cell designs are developed and evaluated in the “Chemistry Lab”. In the “Flexible Cell Lab”, the new developments are produced and tested in automotive pouch cells.

The new building for the second stage is due to be completed by the end of this year. Among other things, this state-of-the-art test and proving centre will house a battery ramp-up factory for product and process development as well as maturity assurance for large-scale industrial production. Various functions of the test centre at the Nabern site will be transferred to the eCampus in Untertürkheim for this purpose. State-of-the-art test benches are being built on an area of around 20,000 square metres to comprehensively test and prove the safety and service life of batteries.

The new Mercedes-Benz eCampus building is located on the site of the former buildings 132/1 and 132/2 in the centre of the Stuttgart-Untertürkheim plant, which looks back on a long and eventful history. The original building 132/1 was built back in 1907 and in its early years housed the production of camshafts and crankshafts. These were used in numerous generations of Mercedes-Benz combustion engines. Over the years, a number of different capabilities were added. These included tool calibration, the central inspection area, the production inspection area for crankshafts and connecting rods and production management for engines. As a competence centre for future drive technologies, the new eCampus plays a key role in the transformation of the plant with a heritage spanning 120 years.

120 years of Mercedes-Benz Untertürkheim

With the new eCampus, Mercedes-Benz is consolidating the role of the largest powertrain facility within its global network, which is celebrating its 120th anniversary this year. Investments in the three-digit million-euro range will strengthen Untertürkheim’s role as a high-tech facility for drive technologies – a clear commitment to the workforce and to Baden-Württemberg as a centre of automotive competence.

Founded in 1904, the Mercedes-Benz Stuttgart-Untertürkheim plant spans several sub-sites in the Neckar valley and set the course for e-mobility some time ago. The plant already produces flexible drive systems for both fully electric and electrified vehicles. Untertürkheim is responsible for the production of drive components. The forge is also located there. Furthermore, the Untertürkheim site is home to a large part of the Group’s drivetrain research and development, with a test track for vehicle testing as well as the new Mercedes-Benz eCampus. The central van division and its research and development is also located here. And Untertürkheim is home to the Mercedes-Benz Group AG headquarters. In total, more than 23,000 employees work there, including sub-sites – around 14,100 of them in production. From 2024, the ramp-up of production of electric drive units for fully electric Mercedes-Benz vehicles will begin at Untertürkheim.

Highly efficient engines are produced in Bad Cannstatt. Axle production for all drivetrains and the foundry are both located in Mettingen. Parts for electric drive units will be manufactured and assembled into electric axles here from 2024. Transmission production is at the Hedelfingen plant. Battery systems for the all-electric EQS and EQE models have also been produced here since 2021. This year will also see the start of production of parts for electric drive units. Flexible production is located in Sirnau and training is based in Brühl. Since 2022, the Brühl plant has been home to a battery factory producing systems for Mercedes-Benz plug-in hybrid models. The ramp-up of production for batteries for all-electric models starts here in 2024.

Closing the battery loop

The opening of the eCampus marks an important step in Mercedes-Benz’s sustainable business strategy. By 2039, the company aims for its fleet of new vehicles to be net carbon neutral over their entire lifecycle. In addition to decarbonisation, one of the most important levers for this is the establishment of a truly circular economy in order to conserve primary resources. Mercedes-Benz is pursuing a holistic approach to batteries, focussing on three core issues: circular design, value retention and closing the loop.

The eCampus activities form the starting point of Mercedes-Benz’s circular concept. With the “Design for Circularity” approach, the company considers the entire value chain of battery technology from the very beginning. From development of new cell chemistries to the testing of battery cells and production in small quantities for the development, the company designs battery cells with “Mercedes-Benz DNA”. The findings flow into the series production of battery cells at partner companies.

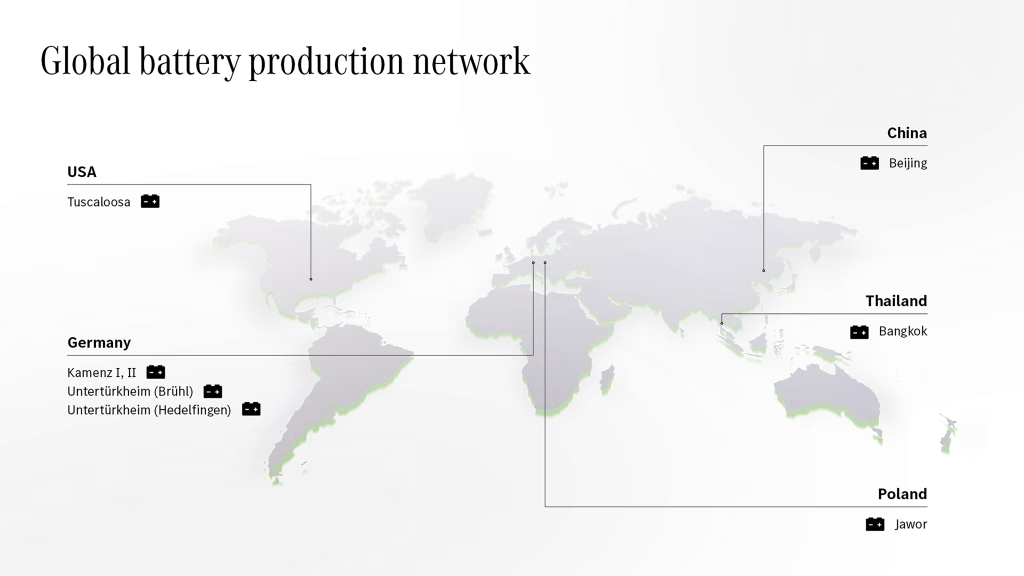

Production of batteries for electric Mercedes-Benz vehicles is net carbon neutral1 at battery factories on three continents – including at the two Untertürkheim plants in Brühl and Hedelfingen. Local battery production is a key success factor for the Mercedes-Benz sustainable business strategy.

The company offers reconditioned batteries as spare parts for all electric vehicles in line with the concept of a circular economy and to conserve resources. In addition, the subsidiary Mercedes-Benz Energy has established a successful business model for large-scale stationary storage applications. Batteries that can no longer be used in the vehicle can be reused in second-life storage systems. Material recycling comes at the end of a battery’s life and is the key to closing the materials loop. An important step in this direction is the opening of a battery recycling factory this year in Kuppenheim in southern Germany.

eCampus with sustainable building concept

The building concept for the new eCampus in Stuttgart-Untertürkheim, which covers more than 30,000 square metres, also meets Mercedes-Benz’s sustainability criteria. Its foundations contain recycled concrete made from demolition materials. More than 75 percent of the usable roof area of the state-of-the-art test and proving centre is equipped with photovoltaic systems and supply the facilities with renewable energy. The entire roof area is also being greened. Reversible heat pumps and cold accumulators enable a sustainable heat supply and air conditioning for the hall. Hybrid cooling towers increase the efficiency of the water supply.

Mercedes-Benz’s own production sites have been net carbon neutral[1] since 2022. By 2030, the plan is to cover more than 70 percent of production energy requirements with renewable energy. This will be achieved through the expansion of solar and wind energy at the sites and the conclusion of further corresponding power purchase agreements. The goal for all Mercedes-Benz production plants worldwide is to operate with 100 percent renewable energy by 2039.

Statements from the opening of the Mercedes-Benz eCampus

“High-performance batteries comprise the heart of the electrification of transport – and are the key to the successful transformation of the automotive industry. The demand for innovative and sustainable batteries will continue to rise sharply in Europe in the coming years. It is therefore of central importance that Germany and Europe build up their own capacities and, in particular, their own expertise in this key technology. This not only strengthens the industrial location and creates modern, future-proof jobs, but also increases Europe’s resilience. I am delighted that with the new eCampus, Mercedes-Benz will be focusing its research and development activities for batteries at the Untertürkheim site in future. Thereby making an important contribution to the further development of battery technology and the establishment of a strong battery ecosystem in Germany.”

Robert Habeck, German Federal Minister for Economic Affairs and Climate Action

“At the new eCampus, we can pool and expand our comprehensive research and development expertise across the entire electric drive system even more effectively. This offers us new opportunities for sustainable innovations in cell chemistry. In Untertürkheim, we cover the entire development process, from cell chemistry to certification. High-voltage batteries are at the heart of electric mobility and their cells are the key to efficiency, energy density and resource conservation. Our aim is to develop the perfect cell design with ‘Mercedes-Benz DNA’ here in Untertürkheim and to incorporate it into our suppliers’ future battery cell generations.”

Markus Schäfer, Member of the Board of Management of Mercedes-Benz Group AG, Chief Technology Officer

“From now on, the heart of the electric car – the battery cell – will also be manufactured in this impressive location at the centre of the heritage Mercedes plant in Untertürkheim. Highly specialised battery storage technology is a promising business model for our country. Those who master it will secure prosperity and jobs – and become less dependent on imports. The state government of Baden-Württemberg has also done a lot to achieve this. As just part of our strategic dialogue on the automotive industry, we have invested 400 million euros in future projects. Altogether, we have invested around one billion euros in the structural transformation of the automotive industry over the past 15 years. The new eCampus is yet another beacon for high-tech battery technology that’s ‘Made in Baden-Württemberg’.”

Winfried Kretschmann, Minister-President of Baden-Württemberg

“For me, the Mercedes-Benz main plant in Untertürkheim is associated with the Swabian spirit of innovation, tinkering and invention. It is fantastic that Mercedes-Benz is setting the right course at this place of inspiration with the new eCampus. The Mercedes star shall continue to shine out into the world from Stuttgart in the future.”

Frank Nopper, Mayor of the City of Stuttgart

“The transformation towards electromobility is changing job roles and duties. That is especially true at our heritage production site for drive systems in Untertürkheim. To successfully shape this change, it will require flexibility first and foremost. Both from us as a company and from our employees. We are supporting our teams through this transformation by offering a wide range of development opportunities with a variety of training programmes and customised coursework. I would like to thank all our colleagues for their willingness to embrace change – and for their great motivation for working together towards a successful future.”

Sabine Kohleisen, Member of the Board of Management of Mercedes-Benz Group AG, Human Resources & Labour Director

“Stuttgart-Untertürkheim has been the centre of highly efficient Mercedes-Benz drive technologies for 120 years. The new eCampus and the new electric products for our plant ensure that this will continue to be the case in the future. Concentrating all aspects of battery technology and production in one place is also an important step in the transformation of the company and the site. With an innovative building concept and the extensive use of renewable energies, we are also consistently realising our sustainability aspirations in Untertürkheim.”

Jörg Burzer, Member of the Board of Management of Mercedes-Benz Group AG, responsible for Production, Quality & Supply Chain Management

“The Untertürkheim drive systems play a key role in the implementation of Mercedes-Benz’s sustainable business strategy. In addition to the development and production of highly efficient drive units, we now also cover the entire field of battery technology here. From cell development to battery production. We can be really proud of this. Together with our dedicated and highly flexible teams in Untertürkheim, we are continuing to write the 120-year success story of our main plant.”

Thomas Schulz, Chairman Mercedes-Benz Drive Systems, Head of Production Powertrain Mercedes-Benz Cars

“In order to offer our colleagues in Untertürkheim long-term security and prospects, we must bring the entire spectrum of electric mobility to our site. This is the commitment of the Works Council. The opening of the new eCampus is an important milestone on this path. It gives Untertürkheim a key role in the transformation of our company.”

Michael Häberle, Chairman of the Works Council at the Mercedes-Benz site in Untertürkheim and Deputy Chairman of the General Works Council of Mercedes-Benz Group AG