In 2025 Automobili Lamborghini is celebrating ten years since it achieved the on-balance carbon neutrality of its production site. The decision to pursue the carbon neutrality certification was a strategic and proactive one, strongly supported by the entire organisation. This vision made the Sant’Agata Bolognese site one of the first facilities within the Audi Group to be certified, and the first in the world to achieve this recognition from the certification body DNV.

“We decided to undertake a courageous journey ten years ago, and we have turned sustainability into strategic leverage for the company’s future. Today we are celebrating an important goal, and above all we are confirming our commitment to a tangible, measurable evolution consistent with the brand’s values,” stated Stephan Winkelmann, Chairman and CEO of Automobili Lamborghini.

“On-balance” carbon neutrality refers to a condition in which, after having adopted measures to reduce its emissions, a company compensates for the residual and unavoidable ones through offsetting projects so as to arrive at a zero net balance. In this context, Lamborghini achieved the carbon neutrality of its Sant’Agata Bolognese Production Site by combining operations targeted at cutting emissions with voluntary offsetting projects carried out worldwide. In this respect, carbon emissions generated while using the vehicle are excluded.

The path, started in 2015 with the certification of the Sant’Agata Bolognese site, has developed over the years by taking new tangible energy efficiency and technological innovation measures, accompanied by compensating for the residual, unavoidable emissions.

An integrated approach: reduce before compensating

In Automobili Lamborghini’s opinion, being on-balance carbon neutral does not mean simply compensating for the CO₂ emissions generated at its production site but instead, first of all, adopting a systematic strategy to monitor and reduce them.

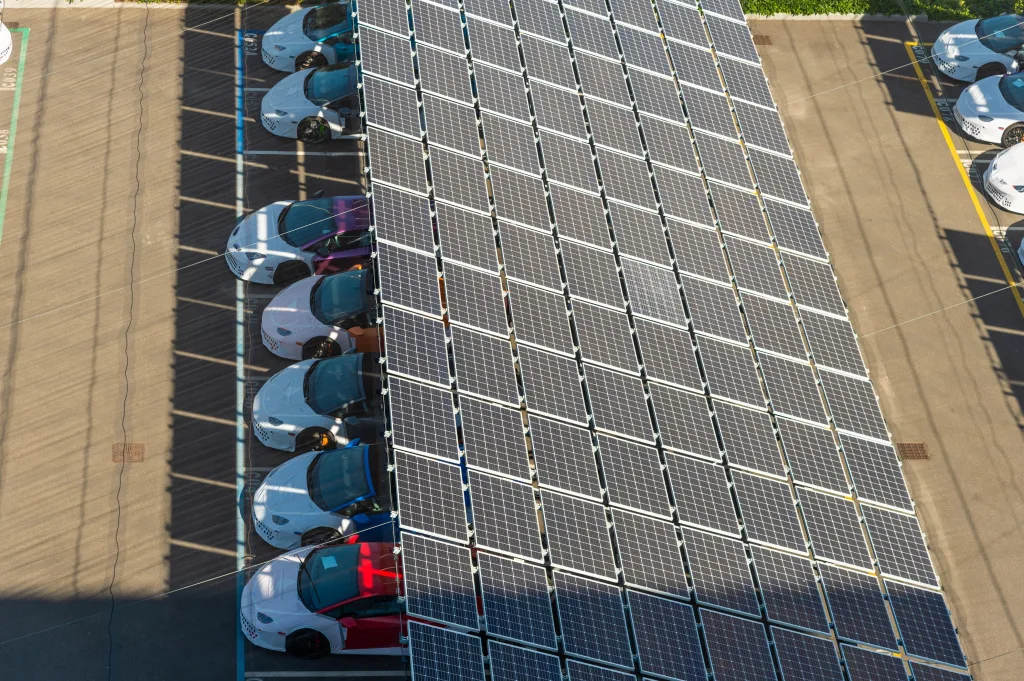

Thanks to an ongoing and well-organized path, over the last ten years Automobili Lamborghini has reduced the emissions of its production site compared to 2014 by 49%, even though the company has doubled in size. It reached this goal by taking targeted measures on processes, technologies and infrastructure, including many energy efficiency actions. Lamborghini’s commitment is deeply rooted. Already in 2010, the first photovoltaic system was installed, and it was later enlarged to cover a total surface area of 15,000 m², one of the region’s most extensive at the time. The system generates and injects over 2 million kWh a year into the power grid, contributing to the reduction of about 800 tons of CO₂ every year. Today Automobili Lamborghini has planned a further expansion of its photovoltaic system as part of its decarbonization strategy, with work involving the warehouse area to be completed by the end of 2025. The already approved investment will offer an additional production of 2,89 million kWh per year, further contributing to the reduction of CO₂ emissions by 1,200 tonnes annually and strengthening the plant’s energy autonomy.

Attention paid to energy efficiency has also impacted the company’s architecture. Torre 1963, the company’s head offices, was inaugurated in 2017 and was certified LEED Platinum with a score of 92 out of 100, the highest ever achieved in Italy at the time.

With reference to gas consumption, on the other hand, two trigeneration plants able to simultaneously produce electricity, thermal energy and cooling energy starting from a single source (natural gas) went into operation in 2015 and 2017. The environmental statements acknowledge their average annual production of 22,000 MWh, with savings estimated at 1,000 tons of CO₂. Lamborghini also became the first automotive company in Italy to adopt a biogas-fueled district heating system in 2015. It is able to supply 3,000 MWh a year of thermal energy and to reduce another 500 tons of CO₂.

Since 2022, Automobili Lamborghini has strengthened its commitment to improving energy efficiency in high-consumption areas through the work of its Energy Efficiency Task Force, significantly enhancing the overall performance of the production site.

“The Sant’Agata Bolognese facility today is a concrete example of how we can combine first-rate manufacturing and environmental responsibility. Every action is the result of an integrated vision that places efficiency, innovation and sustainability at the heart of our everyday operations,” commented Ranieri Niccoli, Chief Manufacturing Officer of Automobili Lamborghini.

Automobili Lamborghini has implemented environmental and energy management systems compliant with the ISO 14001:2015 and ISO 50001:2018 international standards to support this approach, with the goal of optimizing use of resources and improving performance on an ongoing basis. Moreover, keeping its EMAS (acronym of Eco-Management and Audit Scheme) certification, obtained for the first time in 2009, and monitoring emissions according to the ISO 14064-1:2018 standard confirm the company’s commitment to transparent disclosure and strict control of the generated impacts.

The reduction actions were then systematically extended to all emission categories (Scope 1, 2 and 3) along the entire value chain. Automobili Lamborghini is now looking to the future with a clear strategy set out in the Direzione Cor Tauri roadmap, and with the goal of strengthening its sustainable industrial model balanced between engineering excellence and environmental responsibility.

Emissions of the production site and local offsetting initiatives

The emissions of the production site (Scope 1 and 2) in 2024 amounted to 29,849 tons of CO₂, a figure that Automobili Lamborghini has undertaken to reduce as much as possible. The presently residual unavoidable emissions are instead fully compensated for with certified carbon credits.

Automobili Lamborghini started out on this path in 2015 when it chose to invest in concrete initiatives rooted in the local area, initiatives able to generate tangible benefits from both the environmental perspective and for the communities involved. One of these is a mobility plan for cyclists in the Municipality of Bologna, aimed at promoting everyday use of the bicycle as a means of sustainable urban transportation. Another is a carbon capture initiative in the valley of the Venetian lagoon, where eco-friendly filtering systems exploit the combined action of salinity and vegetation to absorb and stockpile atmospheric CO₂.

Since 2022 this approach has been further refined with the company’s decision to select these credits only from among those certified according to the highest international standards, such as the Gold Standard and Verra, favoring projects tied to the production of renewable energy and consistent with the brand’s values and a commitment to concrete and transparent sustainability.

The first Sustainability Report about to arrive

The year 2025 marks not only the tenth anniversary of Sant’Agata Bolognese production site’s carbon neutrality, but a fundamental step taken in the evolution of Automobili Lamborghini’s ESG strategy as well with the publication of the first Sustainability Report in the company’s history.

More than a simple disclosure tool, the Report is an actual governance tool designed to organically and transparently collect the results obtained, the initiatives in progress and future goals. It is a document that will allow the internal environmental, social, and governance performance monitoring to be consolidated while, at the same time, reinforcing communication with stakeholders.

From the decarbonization path to the well-being of people, from efficient management of resources to initiatives in the local area, the Report will clearly, and in a structured manner, relate Automobili Lamborghini’s commitment to an increasingly sustainable and responsible industrial model.