- Milestone for Audi in China: Audi FAW NEV Company begins production of fully electric models exclusively for the Chinese market

- Strategic importance: fully digitalized, state-of-the-art plant to form the centerpiece of a local industrial ecosystem

- Audi CEO Gernot Döllner: “The new plant and the models produced here are a significant step forward in our electrification strategy and for our local portfolio in China.”

Audi FAW NEV Company, a cooperation project between Audi and long-standing partner FAW, has commenced production of all-electric Audi models. The company and its new state-of-the-art plant form a key component of the strategy Audi has adopted for the Chinese market. The new production site in Changchun is the first in China to exclusively produce fully electric Audi models based on the PPE platform, beginning with the Q6L e-tron family, followed by a market-specific version of the Audi A6 e-tron.

Today marks the start of production for the first of these fully electric Audi models based on the PPE platform (Premium Platform Electric) in China. The PPE is the next-generation platform for all-electric vehicles from Audi that set standards in terms of performance, range, charging, and driving dynamics. Audi FAW NEV Company manufactures mid-sized and full-sized PPE vehicles, starting with the Audi Q6L e-tron and the Audi Q6L Sportback e-tron.

A China-specific variant of the Audi A6 e-tron is set to follow. “With the start of production at Audi FAW NEV Company, we are upholding our commitment to the Chinese market and taking a significant step forward in our electrification strategy,” says Gernot Döllner, CEO of AUDI AG: “The models produced here will play a crucial role in our local portfolio and strengthen our position in this key market.”

With the new plant, Audi is expanding its model portfolio for China

The Audi Q6L e-tron is the first electric vehicle based on the Premium Platform Electric (PPE) produced in China. It differs from the international model not only in its traditionally longer wheelbase, but also through numerous design features and innovations for the Chinese market. For example, the interior of the Q6L e-tron impresses with a digital experience also developed specifically for China. Its sister model, the Audi Q6L Sportback e-tron, combines the strengths of the SUV model with a sporty coupé-like silhouette.

“Localized production of market-specific models has always been key to our success in China, and it is essential for the future of Audi to be close to customers,” says Gerd Walker, Member of the Board of Management for Production and Logistics at AUDI AG.

Audi is therefore focusing even more strongly on market-oriented production in the three core regions of Europe, North America, and China. Walker stresses: “With its state-of-the-art, fully integrated, and eco-friendly production, the plant is setting new standards across the Audi production network.”

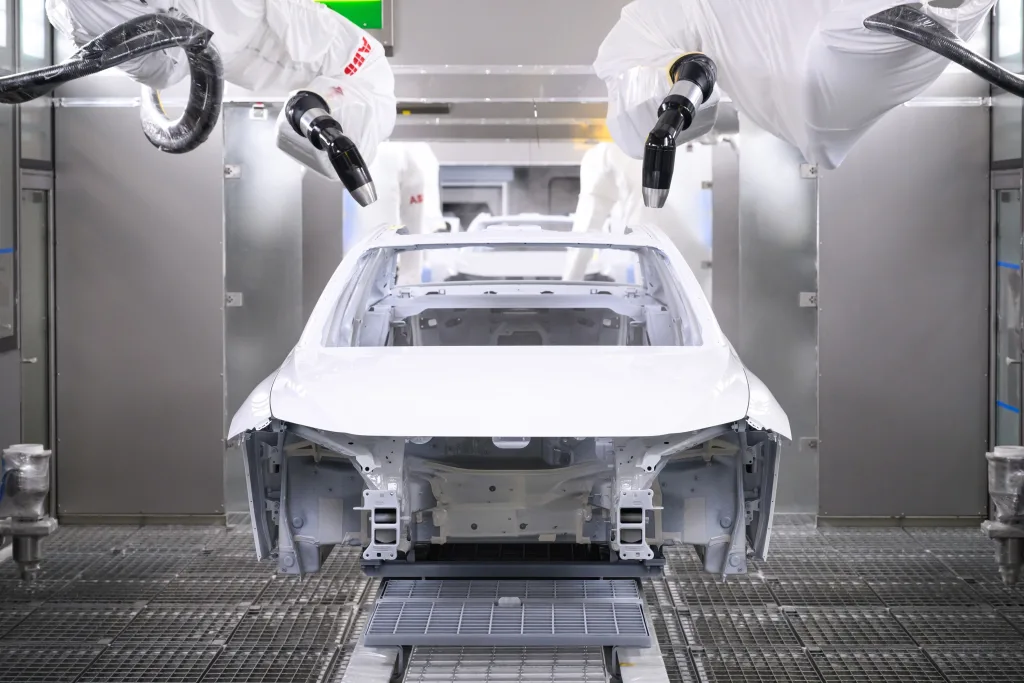

Set up in partnership with Audi’s long-standing partner FAW, Audi FAW NEV Company’s plant in Changchun – FAW’s traditional home – will create around 3,000 new jobs in the future. With a planned annual production capacity of over 150,000 vehicles, the new site is making a key contribution to the electrification of the Audi product portfolio in China. The plant incorporates the entire value chain of automotive production and is equipped with a press shop, body shop, paint shop, and vehicle assembly. Production of the high-voltage batteries for the China-specific PPE models takes place at the plant’s battery assembly facility.

Innovative construction and production technologies

Construction of the production site started in mid-2022, and Audi FAW NEV Company utilized digital technology to design and build the plant from the very beginning. Digital twinning allowed experts to create a highly efficient and flexible production system that is fully digitalized and automated. A 3D structure of the plant’s buildings based on BIM (building information modelling) was set up first, with real-time updates of the digital model continually keeping pace with real-world construction progress.

At the new plant site, Audi is also deploying an integrated IT solution in the Chinese market for the first time. With industry-leading digital manufacturing processes, it facilitates the realization of intelligent and efficient production. All maintenance, logistics, and manufacturing processes across the plant are networked with each other via only one single IT architecture. In a first for Volkswagen Group outside Europe, a highly integrated Group solution using SAP S/4HANA is being rolled out. Using the cloud-based system, data is stored and shared throughout the plant.

Helmut Stettner, CEO of Audi FAW NEV Company, emphasizes the benefits of the high-tech approach taken in Changchun: “Technology helps amplify the synergies between the teams from Germany and China. It also enables us to be fast and highly efficient and speed up processes – both during construction and in day-to day-operation. We create an ideal synergy between our highly skilled workforce and cutting-edge technology at the site.”

Plant-wide automation and enhanced use of robotics

With more than 800 robots enhancing precision and efficiency, the automation rate in the body shop will reach the highest levels in the industry in China. Visual recognition technology ensures quality control, while a partially automated crane in the press shop streamlines operations.

A driverless transportation system and an automatic warehouse guarantee automated and reliable logistics. The warehouse stands 24 meters tall and features fully automated storage, warehousing, and retrieval. Furthermore, Audi is developing new automation technologies at its new plant, like the potential use of humanoid robots in car production.

Audi FAW NEV Company has therefore announced a Memorandum of Understanding (MoU) with the Beijing Innovation Center of Humanoid Robotics and UBTECH ROBOTICS to explore the next step in this technology.

Sustainability at the forefront

Audi FAW NEV Company is committed to sustainability, implementing “Mission:Zero,” the global environmental program for all Audi production sites. Production at the plant is planned to be net carbon-neutral1 from the beginning. To this end, the facility exclusively utilizes green energy. Its heating needs are met using thermal energy and gas obtained from biomass. Solar panels with 320,000 square meters of surface area installed on the roofs of various buildings fulfil a significant portion of the plant’s energy needs. An independent certification for net carbon neutrality is planned for 2025.

The plant recycles production waste and treats wastewater in a closed loop. The latter also includes rainwater collection and reverse osmosis. Implementation of a closed material loop for aluminum offcuts in the press shop as well as a particularly efficient and environmentally friendly paint shop are further highlights.

Biodiversity is another focus at the new production site. Audi FAW NEV Company has carried out landscaping based on the original topography of the area, with many local plant species being planted. A huge area is set aside for the planting of various flowering plants and trees, while another part of the site has been transformed into wetland. Additionally, workers have set up artificial bird nests and insect hotels. Ten beehives on the plant’s grounds are already home to a total of around 500,000 bees. Furthermore, road lighting at the facility is designed to not irritate local fauna.

Future ecosystem and supplier park

In addition to forging a complete talent training system, Audi FAW NEV Company will also facilitate the upgrade of the entire supply chain around the plant. To ensure that the large-scale production of complete vehicles and parts runs smoothly, around 50 percent of suppliers are projected to be within a radius of 30 kilometers of the Changchun site. The local government has also set up an exclusive business park for Audi FAW NEV Company suppliers with a view to attracting more business. The fact that Audi FAW NEV Company is projected to achieve a localization rate of around 90 percent is proof of the effectiveness of the “in China, for China” strategy.

Electrification strategy for China

The start of production at Audi FAW NEV Company is a key step in the further success of the electrification strategy Audi is utilizing in China. In close collaboration with its two partners, the local automobile manufacturers FAW and SAIC, Audi will offer a comprehensive portfolio of vehicles tailored specifically for the Chinese market. Auto Guangzhou 2024 in November of this year showed its newest additions. The premieres of new models highlighted the focus on electrification and digitalization, key pillars of the company’s strategy for China.