- PowerCo- and Umicore-backed joint venture IONWAY scales up EU footprint in the e-mobility business

- IONWAY creates 900 industry jobs in Poland to produce cathode active material (CAM) for EVs, the most valuable battery asset

- First production site will run on renewable energy with a view to carbon-neutral production

- Strong contribution to swift mobility transition and EU Green Deal through regional, sustainable and transparent battery supply chains

- Strategic support from the Polish government under the Temporary Crisis and Transition Framework (TCTF)

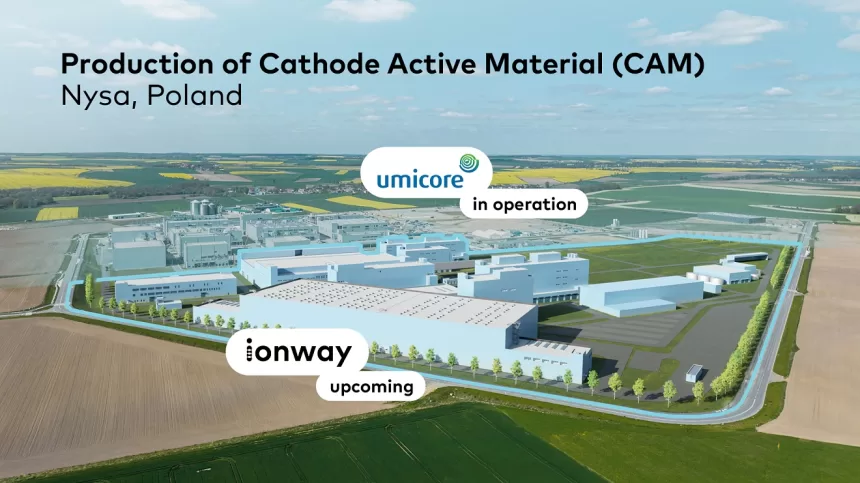

The newly-founded Brussels-based European EV battery materials producer IONWAY has chosen to build its first CAM production plant in Nysa, Poland, adjacent to Umicore’s existing CAM plant. The JV, backed by Volkswagen Group-owned PowerCo SE and Umicore, is scaling up the EU footprint in the e-mobility business with the ambition to grow its annual production capacity to 160 GWh p.a. by the end of the decade, corresponding to 2.2 m battery-electric vehicle, based on market developments. IONWAY will thus help the European Union achieve its Green Deal ambitions by accelerating the establishment of regional, sustainable, and transparent battery value chains.

“We are excited with today’s announcement, as it marks the operational first step of IONWAY and an important step in the expansion of Umicore’s European local-for-local integrated battery materials value chain,” said Mathias Miedreich, CEO of Umicore.

Jörg Teichmann, Chief Purchasing Officer of PowerCo: “IONWAY gives both PowerCo and Umicore a significant first-mover advantage in the fast-growing e-mobility market in Europe. PowerCo has now co-created what it was looking for: a battery materials supplier to secure and build-up manufacturing capacity for reliable and cost-competitive precursor and cathode material production based on responsibly sourced raw materials.”

The Polish government strongly supports the investment in Nysa ‒ which is expected to create about 900 future-proof industry jobs in Nysa towards the end of the decade ‒ and is offering IONWAY € 350 million in cash grants under the Temporary Crisis and Transition Framework for a total investment of up to €1.7 billion (€ 1.35 billion after grants) by the end of the decade. The TCTF fosters support measures in sectors which are key for the transition to a net-zero economy in line with the Green Deal Industrial Plan.

“We are thankful for the Polish government’s support in IONWAY’s choice for Nysa. The strategic location of the joint venture’s battery materials plant in Poland, right next to Umicore’s own battery materials plant, which is still unique in Europe, will further enable the transition to electric driving that is truly sustainable,” added Mathias Miedreich, CEO of Umicore.

Preparation of the site, engineering, and permitting are ongoing and construction will start soonest once the permitting process is completed. Production of the plant is expected to begin as soon as construction is completed, while PowerCo’s CAM demand for the Salzgitter cell gigafactory is secured from the existing production capacity of Umicore in Nysa in time for its start of production in 2025.

IONWAY’s choice for Nysa and Poland is based on their strategic location with access to renewable energy sources to power the plant’s production, as well as a skilled workforce, and follows the support from the Polish government. Moreover, the production facility will benefit from Umicore’s nearby CAM know-how in Nysa and easy access to raw materials from Umicore’s refining operations in Finland.

“Today’s launch of IONWAY signals PowerCo’s and Umicore’s commitment to sustainable progress that makes electric cars affordable for everybody, starting now,” said Thomas Jansseune, CEO of IONWAY.

IONWAY will produce tailored high-performance CAM as well as the related precursor materials (pCAM), and supply it to PowerCo’s European battery cell gigafactories. The site selection for IONWAY’s pCAM plant is ongoing and will be announced at a later date.

As the key technological levers for the performance of rechargeable batteries, pCAM and CAM are essential to a successful powertrain transition towards e-mobility, with ultra-pure CAM being the battery’s most critical and therefore valuable component.